Here's How Decaf Is Made, Both With and Without Additives

Alika Magas | May 12th, 2021

“There is a time and a place for decaf. That time is never, and the place is the trash.” Yeah, that quote is a really funny saying, but it isn’t entirely true. The truth of the statement relates to the type of decaf itself. Why? Because, sadly, decaffeinated coffee has a long standing love affair with chemical additives.

Back in the early eighteen hundreds, Johann Wolfgang von Goethe (yes, the guy who wrote Faust) brought his coffee to a chemist by the name of Friedlieb Ferdinand Runge. The question: “why does this stuff keep me up at night?” Well, Ferdinand was able to separate out the compound which we now call caffeine to provide Goethe with his answer. The next quest was: “is there a way to remove this stuff?”

And so, the decaffeinating process was born. Scientists found that they could use a chemical solvent to bind to the caffeine in the coffee, and only the caffeine, to then evaporate the solvent out along with the chemical Goethe so detested. At first, that solvent was Benzene and was used well up into the mid 1900s. Benzene was later banned as it was proven to be a known carcinogen.

Green coffee beans being submerged in water. It’s important to note that the coffee undergoes the decaffeinating process before they are roasted.

In the years since, the coffee industry has developed a few safer ways to extract those energetic jitters from the drink we all love so much. Sadly, because of the way caffeine behaves as a chemical, the majority of suppliers continue to resort to processes requiring a chemical solvent.

There are two main ways by which to decaffeinate coffee: two versions of this processes we call solvent based which, as you might have guessed, rely on adding manufactured chemical solvents in order to extract the caffeine. Then, there is a process that requires no solvent at all. This process is dubbed a non-solvent process. We’ll start by reviewing the former.

Solvent-based processes are a direct response to the way caffeine acts as a molecule. So, to lay out some basics, you need to understand what’s so tough about extracting caffeine.

There are over 1,000 chemicals at play in a coffee bean, and these all combine with each other to produce the complex flavors, aromas, and behaviors of coffee across all different brewing mediums. However, just like caffeine, these other thousand-plus chemicals are water soluble. If you use water to extract the caffeine, you are also sucking out all the flavor and body right along with it. That’s the exact reason why chemicals are so handy.

In the first type of chemical process, the green (un-roasted) coffee beans are soaked in water for roughly ten hours. This water is then taken aside and agitated with a chemical called Ethyl Acetate. That chemical bonds with the caffeine during the agitation process that lasts for, again, nearly ten hours. The water is then heated up to evaporate the solvent, taking the caffeine right along with it. The remaining water is then tossed back over the original beans where the surviving natural chemicals are soaked back up.

Alternatively, the solvent can be applied directly to the bean by washing them for several hours. Again, that chemical is then heated to evaporate the caffeine out of the bean. More often than not, the solvent at play here is different from the former process and goes by the name Methylene Chloride.

Those two chemicals have big names and a lot of us don’t even know what they are—unless, of course, you studied chemistry in-depth once upon a time. While Benzene was banned because it’s a known carcinogen, the other two chemicals do have their flaws. Methylene Chloride is identified by OSHA as a potential occupational carcinogen. Then why is it still used in the decaffeinating process? Well, the keyword here is occupational which means that only high and consistent exposure to the chemical can be dangerous—and the possibility for that when you drink decaf is rather low. More on that later.

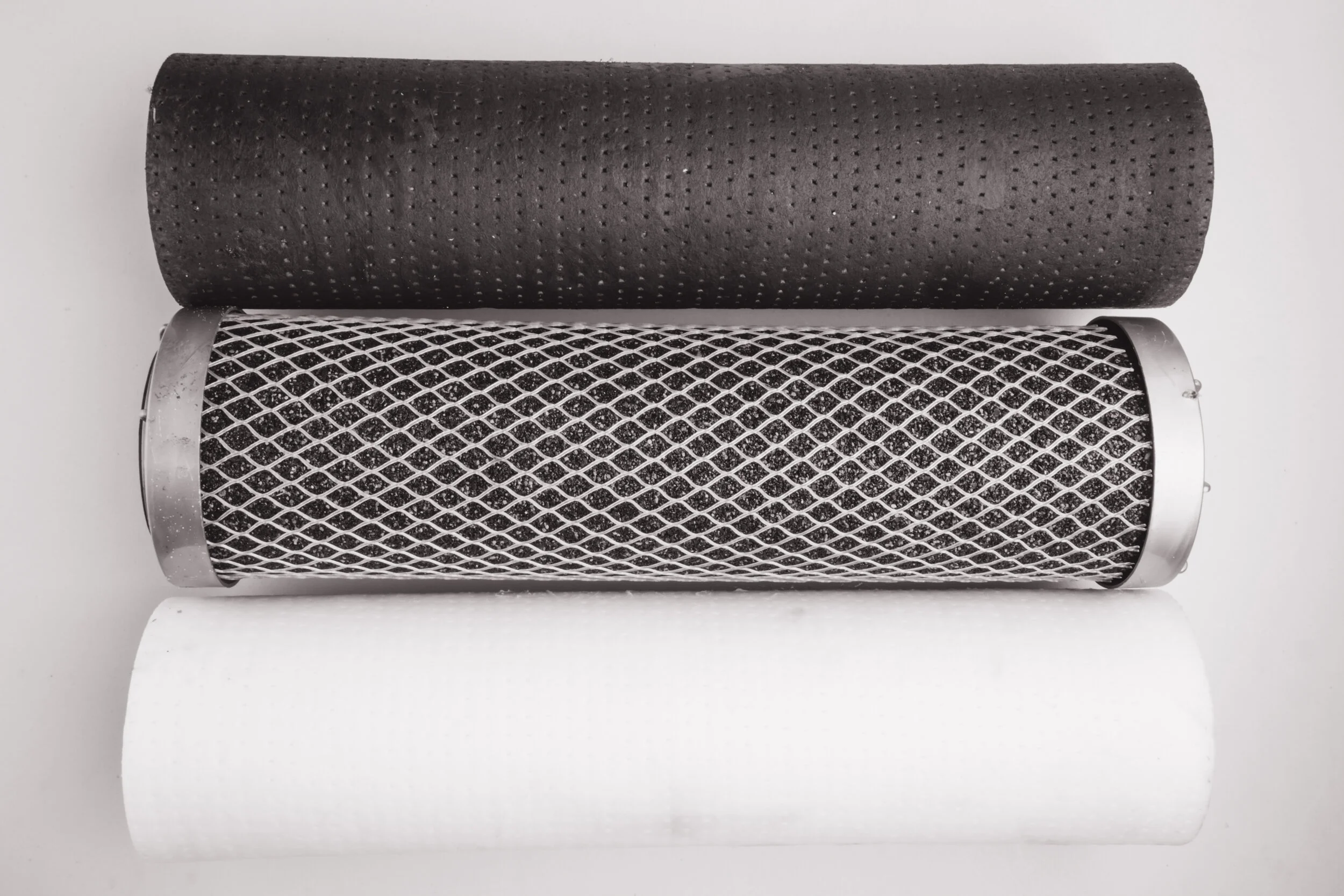

An example of a generic activated carbon filter. While it’s not the same one used in the process, the structure should look familiar. Filters like these are very common in everyday use.

The other chemical, Ethyl Acetate, is a little less scary at first sight. Coffees that are decaffeinated in this manner are often advertised as “naturally decaffeinated”. Companies are allowed to use the word “natural” because Ethyl Acetate is found in nature, specifically in ripe fruits such as strawberries or blackberries. But this name comes with a loophole. Yes, Ethyl Acetate is a naturally occurring chemical, but extracting it from ripe fruits is extremely unpractical. Instead, the compound is produced in a lab. It’s technically natural since its chemical makeup isn’t man made, but that doesn’t mean the chemical itself can’t be made by humans.

Ethyl Acetate also totes health concerns along with it—it has a GHS classification 3 concerning organ and central nervous system toxicity. But the negative effects of both Ehtyl Acetate and Methylene Chloride are induced with high concentrations. They also evaporate very easily, making the FDA’s concern with their use in consumables rather low. However, that doesn’t mean the entirety of the chemical makes it out of your cup of joe. Just enough solvent escapes for there to be no current major health concern.

Here’s the hope: there is a process that doesn’t use any chemicals at all, and it’s the reason you wanted to read this article in the first place. That process has been named the Swiss Water Process and, miraculously, it uses water and water alone. This is how it works.

Green coffee beans are soaked in water to extract all of the chemicals, just as before. And here’s where the night-and-day differences crop up. The now-dead green coffee beans are discarded, and the chemical rich water is run through a carbon filter designed to extract only the caffeine. Now, don’t freak out. Carbon isn’t a chemical, it’s an element and is also the base of all living organisms. Plus, a carbon filter is the same kind of filter that makes sure the water brewing your coffee at your local shop is pure.

Here’s the really cool part. The water now has all the other coffee chemicals, just none of the caffeine. So, the now-decaffeinated water is used to soak new green coffee beans. This is when science becomes decaf’s friend. When there is any sort of organism submerged in a substance saturated with chemicals, nature wants as much balance as possible. This means that if there is caffeine inside the bean, but no caffeine outside the bean, by simple biology alone, all the caffeine will seep out of the bean and into the water. This is based on one simple concept called osmosis. Yeah, the word is fancy, but it literally means something flowing from a high concentration (the caffeine inside the bean) to low concentration (the decaffeinated water outside the bean). What’s even cooler is that the water is reused over and over thanks to the carbon filter. The process doesn’t continuously waste green coffee beans and, because of the absence of chemical solvents, is one of the most sustainable processes in use.

The Swiss Water Logo. Look for it whenever you’re choosing your decaf.